“`html

Building Dreams: A Guide to Constructing Wooden Frameworks

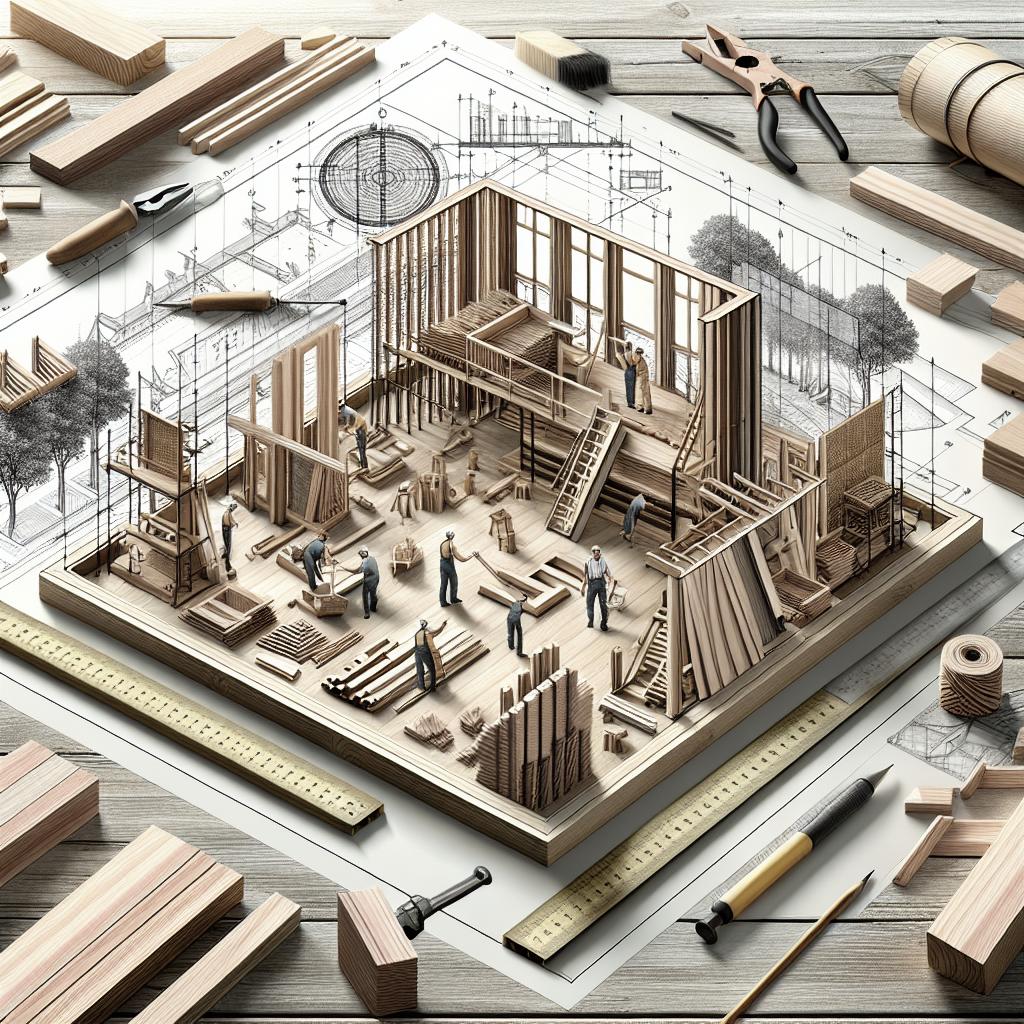

Wooden frameworks have long been crucial to architectural and construction endeavors. Their inherent strength, versatility, and eco-friendliness make them ideal for residential, commercial, and even industrial projects. This blog post delves into the various methods used to construct wooden frameworks, offering insights into the approaches, materials, and techniques. Each method has unique benefits that cater to specific architectural needs and aesthetic visions, from the conventional timber frame system to the innovative modular system. Join us as we explore the intricacies of timber frame systems, site-built techniques, CLT systems, surface unit systems, post and beam systems, and modular systems, shedding light on their distinct characteristics and applications.

Timber Frame System

The timber frame system is a classic method that has stood the test of time, favored for its durability and aesthetic appeal. This approach primarily involves using large wooden beams and posts to create a structural framework. Skilled craftsmen typically pre-cut and shape these timbers in traditional joinery patterns such as mortise and tenon. This not only ensures a robust structural system but also imbues each project with a sense of artistry and craftsmanship.

One of the key benefits of the timber frame system is its ability to support wide-open spaces, making it ideal for buildings that emphasize an open-plan layout. These frameworks harness natural beauty, showcasing exposed beams that add character and warmth to interiors. Furthermore, the use of heavy timbers naturally insulates, which can contribute to energy efficiency in the home.

Site-Built Technique

The site-built technique, often referred to as stick framing, is among the most prevalent construction methods, especially in residential projects. It involves constructing the wooden framework directly on the site, piece by piece. Builders use standard-dimensional lumber, usually light and easy to handle, allowing for quick adjustment and precision in constructing the building’s skeleton.

This method gives architects and builders considerable flexibility in design, accommodating complex layouts and modifications during the construction process. While it can be labor-intensive and reliant on on-site weather conditions, it remains a cost-effective solution for various building types. Its adaptability to different phases of construction and preference for utilitarian design solutions make it a strong choice particularly in areas where customization is paramount.

CLT System

Cross-Laminated Timber (CLT) is a modern, sustainable building material that has revolutionized wooden frameworks by combining performance with sustainability. CLT panels are made by gluing layers of solid-sawn lumber together, with each layer oriented perpendicular to the adjacent layer. This results in strong, dimensionally stable, and rigid panels that are versatile in application.

The CLT system is favored for its quick assembly on-site, facilitated by precision-cut panels manufactured to exact specifications. This method reduces construction time significantly and is a great solution for projects aiming to minimize waste and energy use. Its strength also allows it to compete with steel and concrete in structural applications, making it a material of choice for high-rise buildings striving for eco-efficiency.

Surface Unit System

The surface unit system, or panelized construction, involves building components of a structure in a factory setting and then assembling them on-site. This method often incorporates large wall, roof, and floor panels designed for specific assembly in the field, streamlining the construction process.

By controlling the environment in factories, manufacturers ensure that the components are built to precise specifications, which results in better quality and reducing waste. Onsite, this system facilitates a swift assembly process, significantly reducing labor costs and construction timelines. Due to its efficiency and precision, the surface unit system is ideal for projects with tight schedules or those located in remote areas where traditional labor costs might be higher.

Post and Beam System

The post and beam system is a centuries-old method characterized by its use of heavy timber posts and beams to bear the load of a structure, rather than using lightweight stud walls. This method creates wide-span openings and is lauded for its structural strength and aesthetic flexibility, which often results in open interiors with uninterrupted views.

Architects and builders choose post and beam for its ability to support large, open spaces without interior load-bearing walls. This allows for creative design possibilities in building interiors, as well as the incorporation of large windows and open-plan concepts. Additionally, using natural, visible wood elements adds warmth and beauty, making each structure unique and full of character.

Modular System

The modular system capitalizes on prefabricated building modules, which are factory-produced and transported to the construction site for assembly. Each module is designed to interconnect with others, forming a cohesive structure. This method merges modern technology with construction efficiency, drastically reducing on-site labor and build time.

Modular systems are an excellent choice for projects where time is a critical factor without sacrificing quality or durability. They are increasingly used in residential developments and commercial projects, providing a solution that is both environmentally friendly and architecturally versatile. The ability to replicate modules at scale makes it economically viable and allows for customization within modular frameworks.

Future Prospects: Exploring Wooden Frameworks

| System | Characteristics | Applications |

|---|---|---|

| Timber Frame | Durable, open spaces, artistic joinery | Open-plan buildings, residential projects |

| Site-Built Technique | Flexibility, cost-effective, customizable | Residential construction |

| CLT System | Sustainability, quick assembly, strong | High-rise, eco-friendly buildings |

| Surface Unit System | Factory precision, time-efficient, minimal waste | Tight schedule projects, remote areas |

| Post and Beam | Heavy timber, open spaces, aesthetic | Residential and commercial, open interiors |

| Modular System | Prefabricated, efficient, scalable | Residential developments, commercial projects |

“`