“`html

Techniques for Bending Wood: Your Go-To Guide

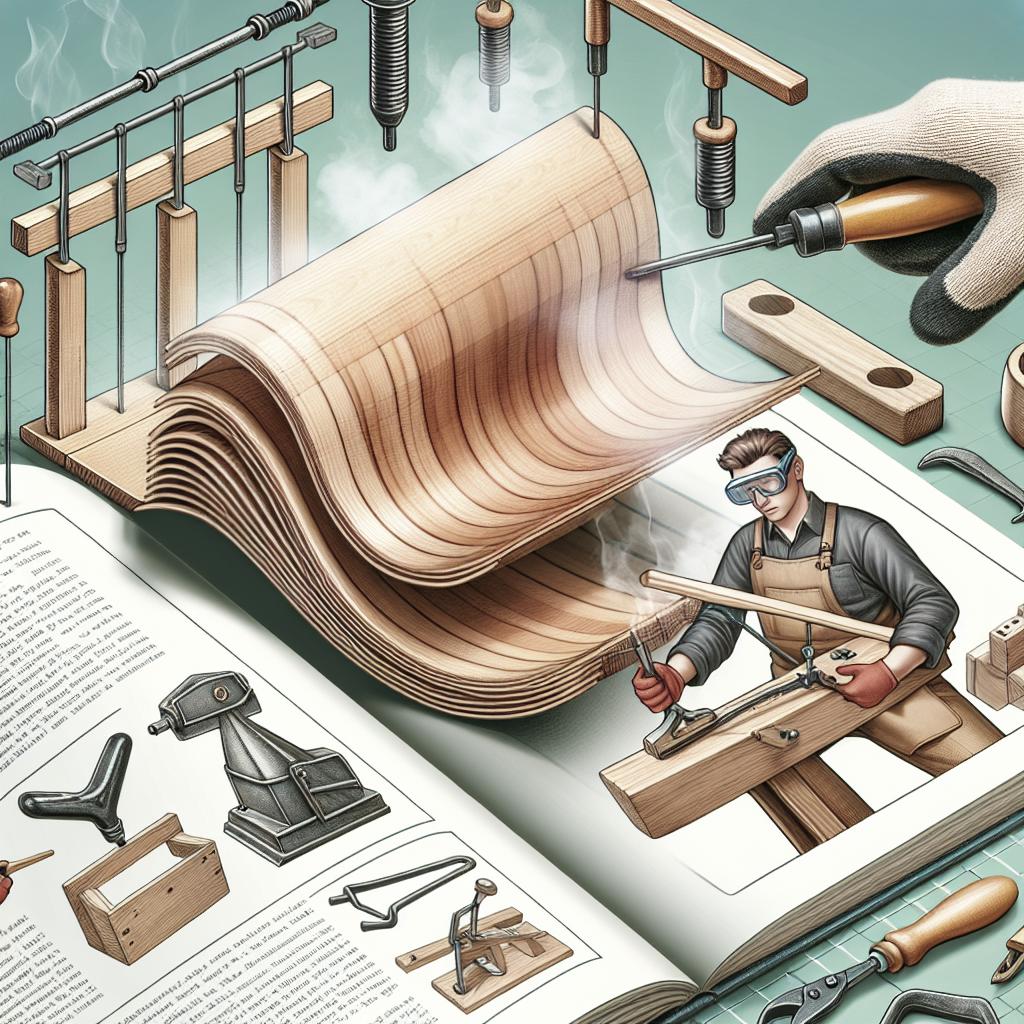

Wood bending is an ancient art and a critical skill for modern woodworking projects, from crafting beautiful furniture to building curved structures. This comprehensive guide will take you through wood bending basics, explain the choice of wood for bending, and describe three main techniques: the kerf-cutting, water-bending, and steam-bending methods. Each method comes with its own set of challenges and advantages. By understanding these techniques, you can decide which method best suits your project needs and resources. Let’s delve deeper into these fascinating techniques and help you create seamless wood designs with elegance and precision.

What Are the Wood Bending Basics?

Before diving into the methods for bending wood, it’s essential to understand the fundamentals. Wood is a natural composite material with its fibers running lengthwise. When bending, the goal is to modify the shape without breaking these fibers. This requires moisture, heat, and sometimes mechanical force, depending on the chosen method.

The first step is conditioning the wood. This involves heating and moistening to increase flexibility. The choice of technique largely depends on the wood’s thickness, species, and intended curve extent. Each method has its own prerequisites and constraints, which need to be respected for optimal results. Understanding these basics ensures that your wood bending project starts on a strong foundation.

Choosing the Right Wood for Bending Projects

Not all woods are created equal when it comes to bending. Some woods, like oak and ash, are renowned for their flexibility and are commonly used in projects requiring bent wood. Woods with straight grain patterns and minimal knot content are typically more conducive to bending.

The moisture content of the wood also plays a crucial role. Freshly cut, or “green”, wood is naturally more pliable compared to seasoned lumber. However, seasoned lumber can be prepped for bending with moisture treatments. Understanding the properties of different wood types will guide you in selecting the best material for your bending projects, ensuring strength and durability in the final product.

What Are the Three Main Ways To Bend Wood?

Wood bending can be achieved through several techniques, each with unique qualities and applications. The three primary methods are kerf-cutting, water bending, and steam bending. Each of these techniques offers distinct advantages and is selected based on the project’s specific requirements and the wood used.

Choosing the right technique is crucial as it affects the efficiency, time, and resources needed to complete the project. Understanding the pros and cons of each method will help refine your approach to achieving seamless and beautiful bends in your woodworking projects.

Kerf-Cutting Method

The kerf-cutting method involves making a series of closely spaced cuts, or “kerfs,” into the wood. This technique effectively reduces the wood’s thickness at the point of bending, allowing it to bend with less resistance. Once bent to the desired shape, the kerf cuts are filled with glue or left as-is to maintain the curve.

This method is often used for projects requiring precise curves in smaller, thinner woods. It’s a practical approach for those without access to steam or water bending facilities. However, care needs to be taken to ensure the cuts do not weaken the wood excessively or cause it to break during the bending process.

Water Bending Method

Water bending involves soaking the wood for a prolonged period, which makes the fibers pliable and easier to mold into the desired shape. This technique is ideal for thinner woods or veneers, which can be shaped with minimal force after adequate soaking.

The main challenge of water bending is the drying time, which can be lengthy. Care must be taken to ensure consistent moisture levels throughout the bending process to prevent cracking. Typically, clamps or molds are used to hold the wood in place as it dries, setting it into the required shape.

Steam Bending Method

Steam bending is one of the most traditional and widely used methods in the woodworking field. This method involves exposing the wood to steam heat, which penetrates and softens the fibers, making the wood more flexible. After exposure to steam, the wood can be bent into a frame or mold to form the desired shape.

Steamed wood cools and dries into a new position, retaining its new curve. This method is favored for larger, thicker pieces that need more structural integrity post-bending. While the setup can be more complex—requiring a steam box and sufficient space—it provides excellent results for experienced craftsmen.

Our Conclusion

Bending wood is both an art and a science, requiring a mix of skill, knowledge, and the right techniques. The kerf-cutting, water bending, and steam bending methods each offer unique advantages, suitable for different project requirements and resource availability. By understanding these techniques and the types of woods best suited for bending, you can enhance the beauty and functionality of your woodworking projects.

Next Up In Woodworking

As you explore the world of woodworking, consider experimenting with advanced joinery techniques or incorporating technology for precision cutting. The intersection of traditional craftsmanship and modern innovation presents endless possibilities for creativity and skill enhancement. Stay curious and continue to refine your woodworking methodologies.

| Technique | Description | Ideal For | Considerations |

|---|---|---|---|

| Kerf-Cutting Method | Series of cuts to reduce wood thickness at the bending point. | Precise small curves, limited setups. | Avoid over-weakening wood with excessive cuts. |

| Water Bending Method | Soaking wood to increase flexibility. | Thinner woods and veneers. | Prolonged drying time, maintain moisture consistency. |

| Steam Bending Method | Using steam heat to soften fibers for bending. | Larger, thicker pieces requiring more structural integrity. | Complex setup, requires steam box and space. |

“`